Opaque, non-obvious, or darkish colored containers shall be inspected only following the complete fourteen working day incubation time period since the contents involve transfer into apparent containers for inspection.

Bacterial Endotoxin (Pyrogen) Testing All large-hazard degree CSPs for administration by injection into your vascular and central nervous methods which have been ready in groups of greater than twenty five identical individual single-dose packages (for instance ampuls, baggage, syringes, vials), or in various dose vials for administration to numerous individuals, or uncovered longer than 12 hrs at two

Media fill test inspection coaching and qualification are actually completed for personnel assigned to media fill test/inspection.

Growth advertising testing shall be done in duplicate (a commencing and an conclude sample established) following the fourteen (fourteen) day incubation employing organisms, inocula counts and incubation circumstances stated in USP , as well as consultant organisms identified throughout environmental checking. Also challenge with any organisms from sterility test positives, if relevant.

All suspect models determined during the observation needs to be introduced on the immediate awareness of your QC Microbiologist.

Identification and Toughness Verification of Substances Compounding services must have no less than the following written treatments for verifying the proper identification and excellent of CSPs prior to These are dispensed and administered: That labels of CSPs bear right names and amounts or concentrations of components; the whole quantity; the further than-use date; the appropriate route(s) of administration; the storage situations; along with other details for Safe and sound use. There are suitable identities, purities, and quantities of components by comparing the initial published order into the penned compounding record for your CSP.

A “media fill” (in some cases often called a “course of action simulation”) here is the performance of the aseptic manufacturing course of action utilizing a sterile microbiological development medium rather than the drug Resolution.

Objects that are not straight subjected to pressurized steam may well end in survival of microbial organisms and spores. Prior to their sterilization, plastic, glass, and metallic products are tightly wrapped in lower particle shedding paper or fabrics, or sealed in envelopes that avoid poststerilization microbial penetration.

I would really like to sign up for newsletters from Sartorius (Sartorius AG and its affiliated businesses) primarily based of my own passions.

Media fill can be a part of aseptic manufacturing system validation. It's performed by replicating the manufacturing method by substituting a sterile microbiological expansion medium to the drug Option.

marketing proprieties for a great deal of microorganisms like germs, yeasts and moulds happen to be proved very often. The anaerobe simulation is restricted for filling traces that are utilized for products filled in an environment wherever oxygen is excluded.

When filter gadgets are assembled from individual nonsterile elements by compounding staff, such gadgets shall be determined to generally here be sterile and ascertained to become successful underneath applicable conditions prior to They're accustomed to sterilize CSPs. By way of example, sterility is often determined applying Organic indicators (see Biological Indicators

in advance of These are sterilized must be tested to make certain that they do not incorporate extreme bacterial endotoxins (see Bacterial Endotoxins Test

Duration of Process, Keeping Occasions and Stopping Moments:- Cut-off dates must be founded for each stage of aseptic processing. Deadlines should incorporate for example the time period between the start of bulk merchandise, compounding and its filtration, filtration procedures, product or service publicity while around the processing line, and storage of sterilised tools, containers and closures. Bioburden and endotoxin load really should be assessed when creating closing dates for levels including formulation processing phase.

Scott Baio Then & Now!

Scott Baio Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Lucy Lawless Then & Now!

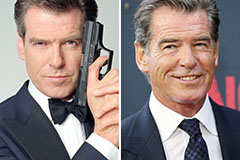

Lucy Lawless Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!